DPF Cleaning: Insights from Successful Farming

- The Enviromotive Experts

- Feb 25

- 2 min read

Updated: Sep 3

Proper diesel particulate filter cleaning is essential for maintaining engine efficiency and emissions compliance. A recent article in Successful Farming by Ray Bohacz highlights the importance of DPF cleaning, explaining how exhaust aftertreatment systems work and why regeneration alone is not enough.

This article breaks down key points from the original publication and provides insights into proper DPF cleaning techniques.

Understanding Diesel Aftertreatment Systems

Modern diesel engines rely on multiple components to reduce emissions and maintain performance. According to Successful Farming, these components include:

EGR (Exhaust Gas Recirculation): Reduces combustion heat and NOx emissions by recirculating inert exhaust gases.

SCR (Selective Catalytic Reduction): Uses DEF (Diesel Exhaust Fluid) to further reduce NOx emissions.

DOC (Diesel Oxidation Catalyst): Converts hydrocarbons and soot into less harmful emissions.

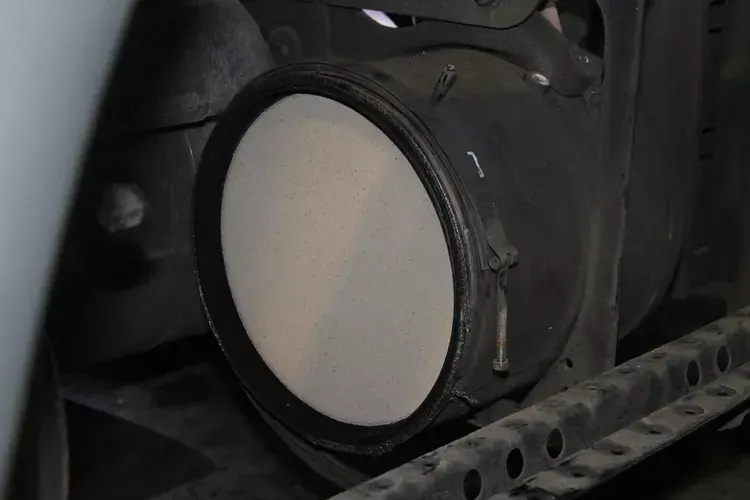

DPF (Diesel Particulate Filter): Captures and stores soot, which is later burned off through regeneration, converting soot into ash.

Why Regeneration is Not Enough

While regeneration helps burn off soot, it does not remove ash, which accumulates over time and clogs the filter.

Types of Regeneration

Passive Regeneration

Occurs naturally when the engine runs at high temperatures.

Takes 20–40 minutes.

Not common for vehicles with short duty cycles or light loads.

Active Regeneration

Initiated by the ECU (Engine Control Unit).

Requires the engine to increase exhaust temperature artificially.

Can take over an hour, during which the vehicle must remain parked.

Since regeneration does not remove ash, periodic deep cleaning is required to prevent excessive backpressure and engine inefficiency.

Steps for Proper DPF Cleaning

According to Successful Farming, proper DPF cleaning involves:

Flow Testing & Weighing – Measures airflow resistance and assesses soot/ash buildup.

Mechanical Cleaning – Uses air pressure and specialized tools to dislodge contaminants.

Lightbox Inspection – Ensures the DPF matrix is intact and undamaged.

Baking Process – Heats the DPF in a 1,000°F oven for 12 hours to burn off contaminants.

Final Flow Test – Confirms that the filter is restored to optimal condition.

Enviromotive: Industry Leaders in DPF Cleaning

At Enviromotive, we provide state-of-the-art DPF cleaning equipment designed to maximize soot and ash removal while ensuring filters remain in peak condition.

If you have questions about DPF cleaning techniques or want to learn about our EvacuBlast and EvacuFlush systems, our expert team is ready to help.

📞 Call 800-954-8265 or email info@Enviromotive.net to discuss DPF maintenance and cleaning solutions.